Tube Qualify

3D Optical Tube Inspection System

The first domestically developed intelligent online inspection system for bent tubes

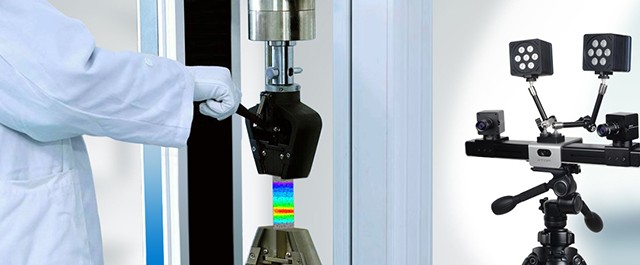

The TUBE QUALIFY 3D optical tube bending measurement system is based on industrial close-range photogrammetry principles and uses high-performance multi-camera spatial calibration, image recognition, and 3D stereo matching technologies. It rapidly captures 3D tube bending data and reconstructs precise 3D models, providing a leading intelligent online inspection and process guidance solution for the tube bending industry.

Take into account the measurement of pipe fittings, pipes, wires, and hoses of different sizes, shapes, and materials in one, and be able to guide the setting and debugging ofthe pipe bender, and reverse the initial sample.

-

Bend test

Specialized measurement of bend parameters

-

Processing guide

Setup and commissioning of pipe bender

-

Reverse engineering

Pipe Registration and Reverse

Application areas

The Tube Qualify tube measurement solution has a fast measurement speed and can realize 100% fully automatic detection. It is suitable for the detection of aero engines, automobile engines, ships and air-conditioning pipe fittings, and can effectively improve tube processing accuracy and production efficiency.

|

Model |

Tube Qualify D8 |

Tube Qualify X10 |

Tube Qualify X16 |

||

|

Product

image

|

|

|

|

||

|

Camera

parameters

|

6M

|

12M

|

6M

|

12M

|

12M

|

|

Number of

cameras

|

8

|

10

|

18

|

||

|

Measuring

tube diameter

|

0.8~50mm

|

0.6~50mm

|

1.2~150mm

|

0.8~150mm

|

1.5~220mm

|

|

Measuring

range

|

550x550x200mm

|

1200x600x400mm

|

2600x1250x700mm

|

||

|

Maximum

measuring tube length

|

Unlimited

(with splicing measurement function)

|

||||

|

Angle

range

|

1~345°

|

||||

|

Measurement

accuracy (sheath deviation)

|

?0.04mm

|

?0.03mm

|

?0.05mm

|

?0.035mm

|

?0.085mm

|

|

Adapter

measurement

|

Not

supported

|

Support

|

|||

|

Automated

communications

|

Not

supported

|

Support

|

|||

|

CAD

digital model editing

|

Not

supported

|

Support

|

|||

Similar Products

XTDIC-Micro 3D Microstrain Measurement

The XTDIC-Micro microscopic application measurement system combines optical microscopy with DIC digital image correlatio...

XTDIC-CONST 3D Strain Measurement

The XTDIC-CONST system is a non-contact optical tool. It uses Digital Image Correlation (DIC) for full-field strain meas...

XTDIC-FLC 3D Sheet Forming Limit Measure...

The XTDIC-FLC system uses Digital Image Correlation (DIC) to analyze sheet metal deformation in cupping tests. It captur...

XTDIC-STROBE 3D Dynamic Measurement

The XTDIC-STROBE 3D dynamic measurement system uses a high-resolution, high-speed digital camera to capture the motion a...

XTOP3D Photogrammetry

XTDP-C Series 3D optical photogrammetry system.